The Era of Industry 4.0: Challenges for Connectors and Effective Solutions

With the arrival of Industry 4.0, manufacturing has become more automated, intelligent, and efficient. This requires production equipment to have higher flexibility and reliability. As connectors play a crucial role in linking electronic devices and circuits, their performance and functional requirements have also increased, demanding connectors that can meet the more complex scenarios found in industrial applications.

Challenges in the Connector Market

- Flexibility Challenges Due to Product Iteration

In downstream industries, product and technology updates happen at a rapid pace. Take the automotive sector, for example, where new vehicle models are constantly being introduced. This creates a need for connectors that offer high flexibility to meet the diverse testing requirements of small-batch, multiple-product lines.

- Demand for Miniaturization and Integration

In the eVTOL (electric Vertical Take-Off and Landing) sector, the equipment contains many electronic components, and space inside the units is extremely limited. This means connectors need to integrate multiple signals—such as power, pneumatic, coaxial, and others—into one compact unit. As a result, connectors are evolving toward miniaturization and higher levels of integration.

- Challenges in Connector Efficiency and Reliability

In the field of automated production, testing stations often perform high-frequency tests—up to several thousand or even tens of thousands of times per year. Connectors, therefore, need to ensure long-term reliability and performance during repeated insertions and removals.

Efficient Interconnection Solutions

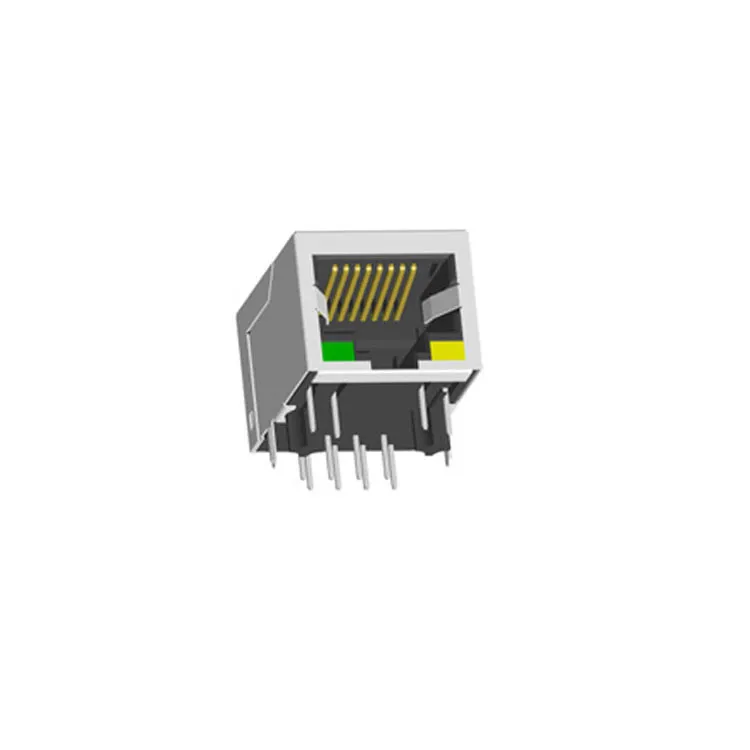

In response to these challenges, modular connectors have emerged as a cost-effective solution that addresses the need for multi-signal types and high integration. The advantages of modular connectors are as follows:

- Multi-Signal Integration

They can integrate signals like power, coaxial, pneumatic, optical, and fluid connections all within one compact framework. This not only saves space but also allows for multiple signal types to be integrated into a single unit.

- Flexible and Efficient

With a modular design, these connectors can be easily adjusted and expanded based on specific testing needs, supporting flexible assembly configurations.

- Reliable and Durable

They are designed to withstand up to 100,000 insertions, ensuring the reliability of long-term connections and reducing the cost of maintenance and replacement over time.

- Fast and Easy to Use

By integrating multiple signals into one connector, the need for multiple cables and connections in test systems is eliminated, making it quick and easy to connect and disconnect the tested units.

To meet the specific requirements of various industries, customized services are also offered. Depending on the actual application scenarios, connectors can be tailored with appropriate interfaces, materials, and protection levels, ensuring stable performance even under extreme conditions like high temperatures, humidity, and vibrations. This further expands the scope of modular connector applications.

To find products and services more accurately, please try entering keywords for search.

For more product and service content, please contact us and send an email to sales@dimud.com.

We sincerely look forward to connecting with you!