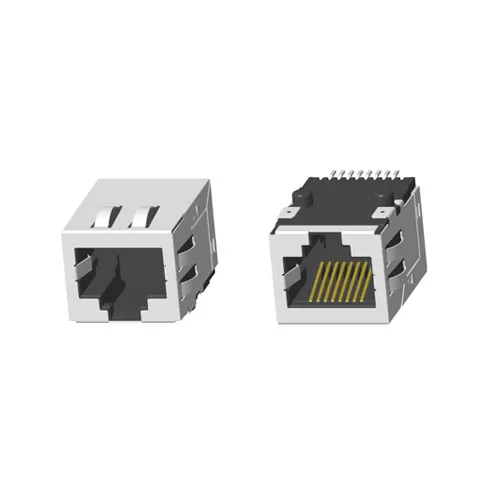

RJ45 Connectors in Factory Automation: Real-World Applications

RJ45 connectors are everywhere in factory automation, helping machines talk to each other smoothly. Let’s look at some real-life examples of how these little connectors make a big difference in various industries.

Example 1: Automotive Manufacturing

At an automotive plant, they connected robotic assembly lines and sensors using RJ45 connectors. This setup allowed the machines to communicate quickly and efficiently over Ethernet.

What Happened?

- They saw a 15% drop in production errors because the robots could share information with quality control systems in real time, thanks to the reliable data transfer of RJ45 connectors.

- Overall, the efficiency of the assembly line shot up by 20% as machines responded faster to changes.

Example 2: Food Processing

A food processing plant struggled with keeping track of inventory. By using RJ45 connectors to link conveyor systems and scanners, they created a better network for data flow.

The Result?

- They improved inventory accuracy by 30% with real-time data updates facilitated by RJ45 connectors.

- This boost in visibility allowed quicker decision-making, cutting down waste by 25%.

Example 3: Pharmaceutical Manufacturing

In a pharmaceutical facility, staying compliant with regulations is critical. RJ45 connectors helped connect temperature and humidity sensors to a central monitoring system.

What Did They Achieve?

- Continuous monitoring led to a 40% reduction in compliance issues, thanks to the reliable communication enabled by RJ45 connectors.

- With real-time alerts, they could act fast to prevent product loss and keep quality high.

Example 4: Electronics Assembly

An electronics assembly line used RJ45 connectors to connect testing machines and robots. This made testing procedures automatic and improved quality checks.

The Outcome?

- They cut testing time by 50%, boosting overall production speed due to the efficient data exchange provided by RJ45 connectors.

- With 35% fewer manual interventions, staff could focus on more important tasks rather than just troubleshooting.

Wrap-Up

These examples show just how important RJ45 connectors are in factory automation. They help machines communicate better, improve efficiency, and keep operations running smoothly. As factories get smarter and more connected, RJ45 connectors will continue to play a key role in making everything work seamlessly.

To find products and services more accurately, please try entering keywords for search.

For more product and service content, please contact us and send an email to sales@dimud.com.

We sincerely look forward to connecting with you!