Molex launches DuraClik 2.00mm wire to board connector

The Molex DuraClik 2.00mm terminal spacing board to board surface welding connector has excellent electrical contact reliability, space utilization efficiency, and strong circuit board retention. The designed connector can be used in strong vibration and high temperature environments, and improves the safety and product performance of the connector.

Molex DuraClik connector series products

-Featured advantages

*Ensure a secure connection between the connector and the printed circuit board

*The sturdy secondary lock enables the terminal to withstand a holding force of 100N (equivalent to 10Kgf) to meet the anti vibration requirements of automobiles.

*Confirm correct and secure connection: durability+interlock confirmation click sound=DuraClik

*When interlocked, a clicking sound can be heard and equipped with a built-in inertia lock. This design can meet up to 15 bit circuits, helping to ensure the reliability of the connection.

*Provide greater design flexibility

*Different board end options (vertical and horizontal) are available for 2 to 15 bit circuits.

*Provide a secure connection and save space; Prevent the lock buckle from being damaged due to wire entanglement

*The internal forced locking device can prevent accidental disconnection of the connection.

*Provide automotive grade reliability

*The ISL version complies with LV214 (S2 anti vibration standard), ES91500-03, and SAE/USCAR-21 standards.

*Allow use in the passenger cabin of premium cars

*The working temperature range of Molex DuraClik is -40 to+130 degrees Celsius, ensuring connection reliability under harsh conditions.

Application scenarios

EV

Battery Management System

Inverter fasteners

Vehicle Connection

automobile

Headlights

Rear combination lamp

Steering switch

transmission case

Information processing module

Head up display

DC-DC converter

Instrument system

Door module

Rearview mirror

Car charger

Distribution device

Seat adjuster

sensor

Navigation system

LED lighting

Variable speed transmission

White goods

commercial vehicle

Tractor

Consumer products

White goods

LED lighting

Crane

Electromagnetic furnace

vending machine

Industrial Machinery

recreational machines

Energy storage system

Battery Management System

inverter

Electromagnetic stove surface

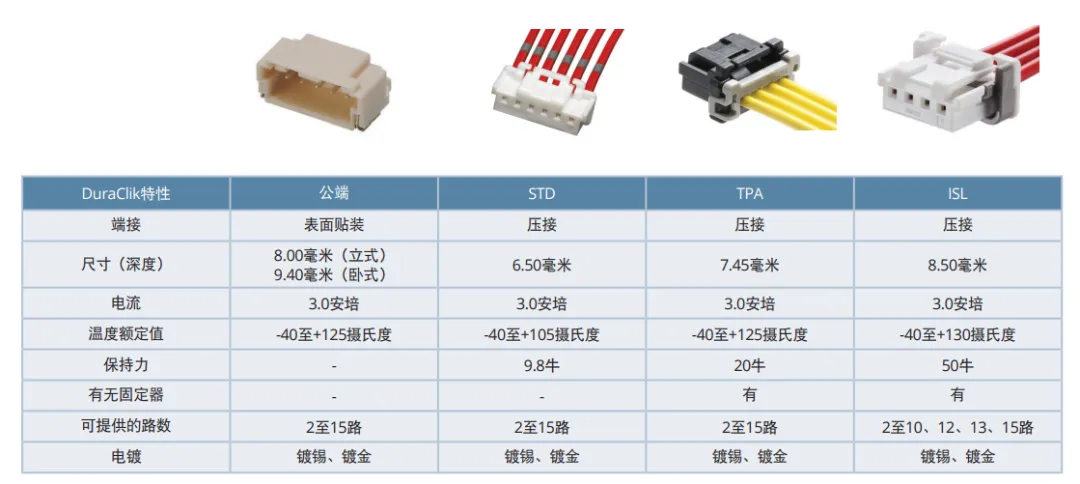

Specification parameters

reference information

Packing:

Male connector - carrier tape and reel packaging

Plastic shell and terminal holder - bagged

Terminal - scroll packaging

Design measurement unit: millimeters

Does it comply with RoHS standards: Yes

Is it low halogen: Yes

Electrical parameters

Voltage (maximum): 125 volts

Current (maximum): 3.0 amperes

Contact resistance (maximum): 10 milliohms

Insulation withstand voltage: 500 volts AC

Insulation resistance (minimum): 1000 megaohms

Mechanical parameters

Terminal contact and female end plastic shell retention force: Standard version -9.8N TPA version -20N ISL version -50N Robust version -100N

Physical parameters

Plastic shell: Standard version, ISL version, and Rubust version: PBT; TPA version: PA

Terminal holder: PBT

Base shell: Polyamide

Base terminal: Copper alloy

Terminal contact: phosphor bronze

Electroplating: Contact area - tin plating or gold plating

Welding tail area - tin plating

Bottom layer - nickel plating

Working temperature: -40 to+105 degrees Celsius (standard) -40 to+125 degrees Celsius (TPA, Robust) -40 to+130 degrees Celsius (ISL)

To find products and services more accurately, please try entering keywords for search.

For more product and service content, please contact us and send an email to sales@dimud.com.

We sincerely look forward to connecting with you!