How RJ45 Connectors Power Industrial Automation

In the world of industrial automation, everything from machines on the factory floor to sensors and control systems is becoming more interconnected. These devices need to talk to each other in real-time to keep operations running smoothly, safely, and efficiently. One crucial component that makes this communication possible is the RJ45 connector.

You might recognize RJ45 connectors as the plugs you use to connect your home internet or network cables. But in the world of industrial automation, these connectors are far more important than you might realize. They allow machines, computers, and sensors in factories to exchange data, making automation systems smarter and more reliable.

In this article, we'll take a look at how RJ45 connectors are helping to power industrial automation and why they’re so essential for modern industries.

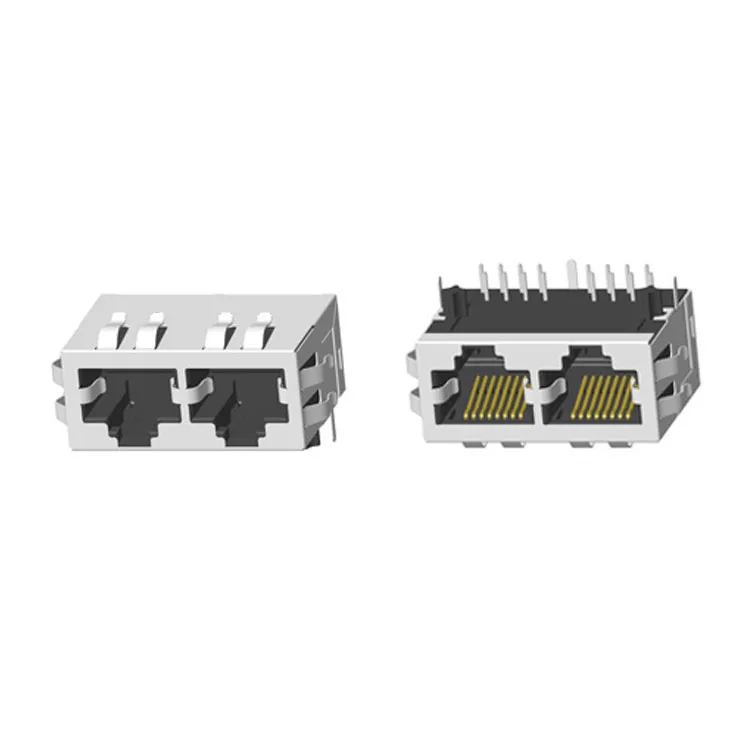

What Is an RJ45 Connector?

An RJ45 connector is a type of plug used at the ends of Ethernet cables, the same cables you use to connect devices to the internet at home. These connectors have eight small pins inside that create a connection between the cable and a device—like a computer, sensor, or industrial robot—allowing them to communicate with each other over a network.

In factories, plants, and warehouses, Ethernet cables with RJ45 connectors are used to link a wide range of machines and devices. These connectors enable fast, reliable communication, which is essential for keeping everything working together smoothly.

Why Are RJ45 Connectors So Important for Industrial Automation?

As industries become more dependent on automation, the need for machines, robots, and control systems to communicate instantly has grown significantly. Here’s why RJ45 connectors are crucial for the systems that power modern factories:

- Reliable and Fast Communication

Industrial operations, from assembly lines to robotic arms, rely on fast and accurate communication between devices. If data isn't transmitted reliably, it can lead to delays, mistakes, or even equipment breakdowns.

RJ45 connectors are designed to support high-speed data transfer, meaning that information can flow quickly and accurately between different devices, such as sensors, machines, and control systems. Whether it’s updating machine settings or relaying sensor readings, these connectors ensure that everything stays in sync.

For example, on a production line, robots need to be constantly updated with real-time data on what parts to assemble or how to adjust. RJ45 connectors make sure that these updates happen instantly, ensuring the whole process runs smoothly.

- Tough Enough for Industrial Environments

Industrial environments are often harsh. There’s dust, extreme temperatures, vibrations, and even potential exposure to moisture. Despite these tough conditions, RJ45 connectors can be built to withstand the wear and tear of factory floors and warehouses.

Industrial-grade Ethernet cables with RJ45 connectors are specifically designed to handle these environments. They are rugged, durable, and resistant to damage, which means they can keep communicating even in challenging conditions.

- Easy to Install and Maintain

One of the reasons RJ45 connectors are so widely used in industrial automation is that they are simple to install and maintain. Setting up a network with Ethernet cables and RJ45 connectors doesn’t require specialized equipment or complex processes, which reduces installation time and costs.

If something goes wrong, technicians can quickly identify which connection is causing the issue and replace the faulty connector or cable, without having to overhaul the entire system. This ease of use helps ensure that industrial automation systems stay up and running with minimal downtime.

- Real-Time Monitoring and Control

In industries like manufacturing or energy, operators need to monitor systems in real-time. This could mean checking how machines are performing, ensuring that production speeds are optimal, or watching for any signs of malfunction that could cause delays or safety issues. RJ45 connectors are key to making this real-time monitoring possible.

For example, in a factory setting, sensors might track temperature, pressure, or machine health. This data travels via Ethernet cables with RJ45 connectors to a central control system, where operators can see the data instantly and make decisions based on the current conditions. If something goes wrong, they can react quickly, helping to prevent costly issues.

- Enabling Smart Factories with the Industrial IoT

One of the biggest trends in modern industrial automation is the rise of the Industrial Internet of Things (IIoT), where devices, machines, and systems are connected to the internet, sharing data and making smarter decisions. RJ45 connectors are fundamental to this IIoT revolution.

By linking machines, sensors, and controllers with Ethernet networks, RJ45 connectors enable devices to send and receive data from cloud-based systems or central control platforms. This allows for predictive maintenance (identifying problems before they happen), more efficient production, and smarter decision-making across the factory floor.

Common Uses of RJ45 Connectors in Industrial Automation

Here are a few examples of how RJ45 connectors are used in industrial settings:

- PLC Networks: Programmable Logic Controllers (PLCs) are central to industrial automation, controlling everything from robotic arms to conveyor belts. RJ45 connectors help these devices communicate with each other, ensuring that production runs smoothly.

- Robots on Production Lines: Industrial robots rely on fast communication to perform tasks like assembling products, testing materials, or packaging. Ethernet networks using RJ45 connectors allow robots to work together and receive real-time updates from central control systems.

- Sensors and Actuators: Sensors monitor environmental conditions, while actuators control physical movements, like opening a valve or adjusting a conveyor belt. RJ45 connectors link these devices to the control system, enabling them to respond to changes as they happen.

- SCADA Systems: Supervisory Control and Data Acquisition (SCADA) systems are used to monitor large-scale industrial processes like power plants or water treatment facilities. RJ45 connectors help link sensors and controllers to SCADA systems, ensuring everything is operating as it should.

Conclusion

The role of RJ45 connectors in industrial automation can’t be overstated. These connectors make it possible for machines, sensors, and control systems to communicate with each other reliably and efficiently. By enabling high-speed data transfer, supporting real-time monitoring, and connecting everything together in a flexible and cost-effective way, RJ45 connectors are helping industries across the world become smarter, more efficient, and more connected.

As industries continue to embrace the Industrial Internet of Things (IIoT) and automation technologies, the importance of Ethernet networks and RJ45 connectors will only continue to grow. These small but essential connectors are key to creating the factories of the future—factories that are faster, more efficient, and more adaptable to the challenges of tomorrow.

To find products and services more accurately, please try entering keywords for search.

For more product and service content, please contact us and send an email to sales@dimud.com.

We sincerely look forward to connecting with you!